Lactate

Redox Tech feels that ABC and ABC+ are superior products for bioremediation. Nonetheless, we recognize that many companies have already permitted sodium lactate for their projects. Given the enormous amount of lactates that Redox Tech purchases, we can also offer sodium lactate and ethyl lactate as pure products. We feel that ethyl lactate is superior to sodium lactate, so you may wish to consider that in the future over sodium lactate. The use of ethyl lactate is covered by our exclusive patent to the Semprini et al patent issued by Oregon State University.

products for bioremediation. Nonetheless, we recognize that many companies have already permitted sodium lactate for their projects. Given the enormous amount of lactates that Redox Tech purchases, we can also offer sodium lactate and ethyl lactate as pure products. We feel that ethyl lactate is superior to sodium lactate, so you may wish to consider that in the future over sodium lactate. The use of ethyl lactate is covered by our exclusive patent to the Semprini et al patent issued by Oregon State University.

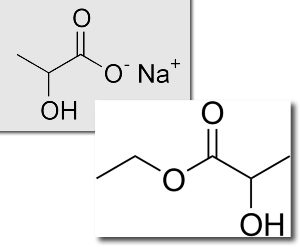

Different microorganisms compete for the same food source. For example, both dechlorinators (the ones that degrade chlorinated organics) and methanogens (the ones that produce methane) can use hydrogen released from food sources as electron donor. At low hydrogen partial pressure, dechlorinators outcompete methanogens. Whereas at high hydrogen partial pressure, most of the hydrogen is wasted by methanogens and dechlorinators can’t thrive (Fennell et al., 1997; Smatlak et al., 1996; Yang and McCarty, 1998) . It is important to deliver a food source to subsurface such that a low hydrogen partial pressure can be maintained to impart a competitive advantage to dechlorinators. One of the most effective food sources for dechlorinators are fatty acids, such as sodium lactate or ethyl lactate. Both sodium lactate and ethyl lactate are commonly used as food additives and therefore readily available, environmentally benign, and fairly inexpensive.

Ethyl Lactate Compared to Sodium Lactate

Redox Tech can provide sodium lactate or ethyl lactate at 60 weight percent. The prices of these two solutions are comparable with each other. The use of ethyl lactate is covered by Redox Tech’s exclusive license to U.S. Patent 6,472,198. Redox Tech recommends injection of ethyl lactate over a sodium lactate solution, for the following reasons:

- Ethyl lactate at 60 percent has a very strong cosolvency effect, which means it can increase the solubility of DNAPL compounds, like PCE, by orders of magnitude, and therefore dramatically increase the efficiency of solvent extraction;

- Upon contact with water, ethyl lactate slowly hydrolyzes to ethanol and lactate, which can both serve as electron donors for anaerobic biodegradation. The electron donor capacity of ethyl lactate is about twice of that of sodium lactate given the same mass (Table 1). On the other hand, sodium lactate releases sodium and lactate. Obviously, sodium does not serve as an electron donor.

- The hydrolysis of ethyl lactate is a slow process, meaning it can serve as a long-term, slow-release hydrogen source, whereas sodium lactate produces a hydrogen “burst” over a short period (Fennell et al., 1997) ;

- The slow hydrolysis of ethyl lactate results in a low hydrogen partial pressure, which is favored by contaminant biodegradation. This means that the hydrogen released from ethyl lactate injection is more channeled toward contaminant degradation rather than wasted on un-targeted microbial processes (Fennell et al., 1997; Smatlak et al., 1996; Yang and McCarty, 1998) ;

- The viscosity of 60 percent sodium lactate solution is about 30 times of that of 60 percent ethyl lactate solution, making the injection of former much harder than the latter (Table 1).

- The density of 60 percent ethyl lactate (1.03 g/mL) is closer to that of water than the density of 60 percent sodium lactate (1.32 g/mL), therefore the former would result in a less extent of density-induced fluid under-ride during injection.

| Property | 60% Ethyl Lactate | 60% Sodium Lactate |

|---|---|---|

| Cosolvency effect | Yes | No |

| Electron donor capacity (mole of H2 released per mole of compound fermented) | 12 | 6 |

| Hydrogen release speed | Slow | fast |

| Viscosity (cPs) | ~3 | ~100 |

| Density (g/mL) | 1.03 | 1.32 |

| Price (per pound) | ~$1.00 | ~$1.00 |

References:

Fennell, D.E., Gossett, J.M. and Zinder, S.H., 1997. Comparison of butyric kid, ethanol, lactic acid, and propionic acid as hydrogen donors for the reductive dechlorination of tetrachloroethene. Environmental Science & Technology, 31(3): 918-926.

Smatlak, C.R., Gossett, J.M. and Zinder, S.H., 1996. Comparative kinetics of hydrogen utilization for reductive dechlorination of tetrachloroethene and methanogenesis in an anaerobic enrichment culture. Environmental Science & Technology, 30(9): 2850-2858.

Yang, Y.R. and McCarty, P.L., 1998. Competition for hydrogen within a chlorinated solvent dehalogenating anaerobic mixed culture. Environmental Science & Technology, 32(22): 3591-3597.