RTB-1

Bioaugmentation For The Treatment Of Chlorinated Ethenes

Redox Tech has experience with chemical oxidation (Fenton’s chemistry, permanganate, persulfate, and ozone), bioremediation (biosparging, cometabolic, sodium lactate (ABC®) and biostimulation), and metals treatment via eH-pH manipulation. We now offer bio-augmentation solutions for sites lacking adequate indigenous bacterial populations to achieve full remediation.

Definition of Bioaugmentation

Bioaugmentation is defined as the addition of high-performance microbial cultures capable of degrading target contaminants. Bioaugmentation for the treatment of chlorinated ethenes entails the addition of a naturally-occurring, non-pathogenic, microbial culture that contains Dehalococcoides sp., which are capable of completely dechlorinating PCE, TCE, and their daughter products to harmless ethene.

Types of Application

• Injection for in situ treatment

• Inoculation of bioreactors

• Use of indigenous or exogenous microorganisms

When Does it Make Sense?

• Incomplete dechlorination following biostimulation

• Inadequate microbial activity

• Accelerated site closeout

Redox Tech’s Dechlorinating Consortium: RTB-1

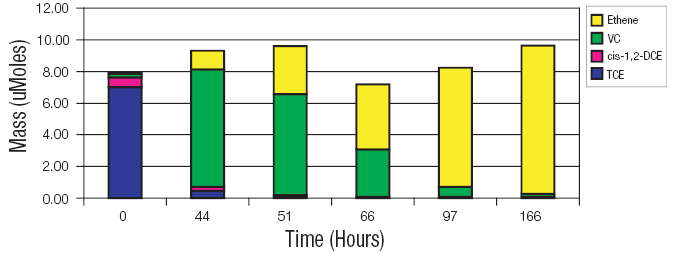

Redox Tech offers an enriched dechlorinating culture capable of efficiently degrading PCE, TCE, cis-1,2-DCE, and VC to innocuous ethene. Not all Dehalococcoides sp. in nature dechlorinate VC efficiently. The Dehalococcoides present in RTB-1 dechlorinate VC to ethene via halorespiration, and not via less efficient cometabolic processes. Figure 1 illustrates complete remediation using an active and effective bacteria like RTB-1.

Figure 1. Contaminant degradation using RTB-1.

Indigenous Enrichments

Redox Tech can develop indigenous enrichments from contaminated site media for potential use during bioaugmentation. The enrichment process will also determine whether the indigenous Dehalococcoides sp. are capable of completely dechlorinating the chlorinated solvents to ethene.

Growth and Scale-Up RTB-1

Redox Tech has access to state-of-the-art facilities for the growth and scale-up of RTB-1 or other cultures. The consortium is successively scaled-up using various-size fermentors ranging from 7 liters to 750 liters (Figure 2). The culture is provided lactate as a carbon source and PCE or TCE as an electron acceptor. The achievement of the appropriate Dehalococcoides sp. cell density is monitored using real-time qPCR. For ease of shipment, the culture is concentrated and transferred into 5-gallon gas-tight kegs (Figure 3).

Figure 2. 750 liter fermentor.

Figure 3. 5 gallon gas-tight keg.

In Situ Bioaugmentation

In situ bioaugmentation for treating chlorinated ethenes entails injecting indigenous or exogenous (e.g., RTB-1) microorganisms to facilitate complete and rapid dechlorination. In situ bioaugmentation is typically combined with the addition of a carbon substrate and microbial nutrients to provide adequate conditions for the proliferation of the dechlorinating microorganisms. If necessary, in situ bioaugmentation may be combined with methods that enhance groundwater flow velocities to facilitate the dispersion of the microorganisms and the nutrients. Redox Tech is one of the leading providers of in situ injection services for environmental remediation. Our experience, innovative tools, and methods ensure the best possible targeted zone of remedial influence.